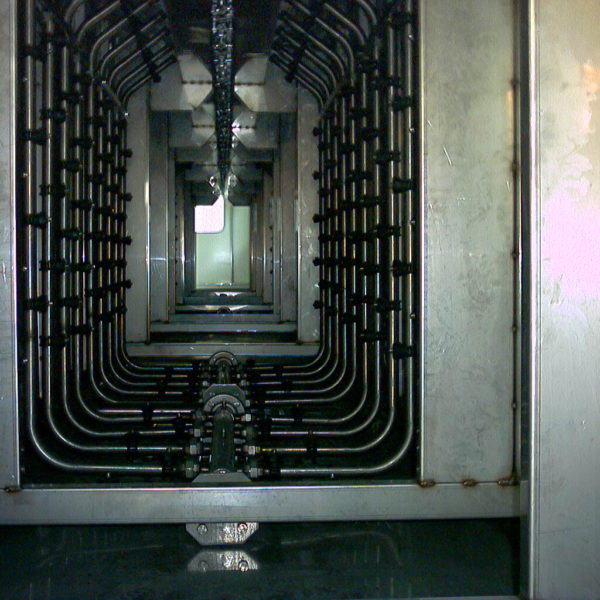

Wash machinery and treatment tunnels for material surfaces are manufactured and differ according to customer needs.

Wash machinery is prearranged to perform the following operations: phosphodegreasing with heat, cold rinse and demi water rinse. The part loading and unloading stages can be performed manually or automatically.

The treatment tunnels differ from the wash machinery as the part to be treated is handled by an air conveyor. The first stage of the surface treatment takes place in the wash tunnel where the part is cleaned degreased and rinsed, making it ready for the subsequent stages of drying, painting and cycle completion.

The design of the wash machinery and tunnel incorporates the use of a chemical specialised in the treatment of surfaces. This consideration is fundamental for both the choice of construction materials and selecting the most suitable degreasing products to use during the wash cycle.