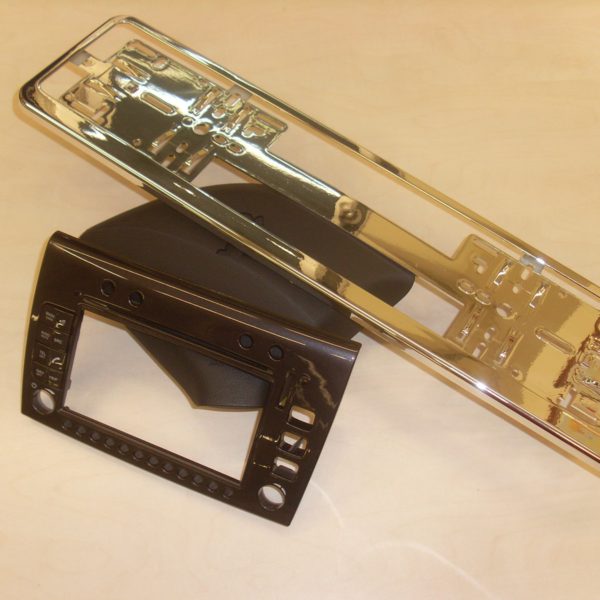

M.I. DUE produces complete component paint lines for the automotive sector. Examples of the painted detailing of components in the automotive sector to which we refer include: buttons, knobs, frames, handles, rear view mirrors, brakes and wheel covers.

M.I. DUE offers technological solutions for the use of different paints, such as water and solvent-based paints, heat polymerisation or UV and soft touch paints.

The application of paints is performed by HVLP spray guns, both fixed and portable, manual or automated. Paint can be applied electrostatically, which significantly reduces overspray.

Our paint lines, based on customer need, can be integrated with vacuum metal-coating plants and robots to automate the process of loading and unloading parts.

The lines manufactured by M.I. DUE are completely pressurised and climate controlled to achieve the highest levels of performance in terms of quality of the painted goods, flexibility of use, reduced maintenance and low operating costs, in addition to paying particular attention to protecting the environment.

Paint lines for the automotive sector can be designed by selecting from a number of alternative processes.

With regard to booths and ovens, available as electric or gas powered models, our production includes:

- Water veil spray booths

- Dry filtration booths

- Paint polymerisation ovens with hot air

- UV curing ovens

- IR curing ovens

Paint lines for the automotive sector are also manufactured and tailored to the space made available by the customer, and are sized accordingly.